Add to Cart

Overhead Bare Electric Cable ACSR Tern 45/7 Aluminum Conductor Steel Reinforced Transmission Lines ASTM B232

Application

ACSR conductors are widely used for electrical power transmission over long distances, since they are ideal for long overhead lines spans. They are also used as a messenger for supporting overhead electrical cables.

Bare Conductor Electrical Cable STANDARD

Basic design to BS 215-2 / BS EN 50182 / IEC 61089 / ASTM B 232/B 232M / DIN 48204 / JIS C 3110 / NBR 7270 standards.

Note: The values of current rating mentioned in above Table are based on wind velocity of 0.6 metre/second, solar heat radiation of 1200 watt/metre2, ambient temperature of 50° C & conductor temperature of 80°C.

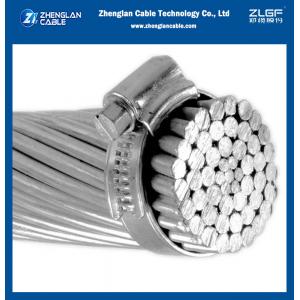

Bare Conductor Electrical Cable CONSTRUCTION

ACSR conductors are formed by several wires of aluminium and galvanized steel, stranded in concentric layers. The wire or wires which form the core, are made of galvanized steel and the external layer or layers, are of aluminium. Steel core wire is available in Class A , B or Class C galvanization for corrosion protection. Additional corrosion protection is available through the application of grease to the core or infusion of the completed conductor with grease. Its core consist normally of 1, 7 or 19 wires. The diameters of steel and aluminium wires can be the same, or different.

ELECTRICAL PROPERTIES

| density@20ºC | Aluminium: 2.703 kg/dm |

| Galvanised Steel: 7.80 kg/dm | |

| Temperature Coefficient@20°C | Aluminium: 0.00403 (°C) |

| resistivity@20°C | Aluminium: Should not exceed 0.028264 |

| linear Expansivity

| Aluminium: 23 x10 (°C) |

| Galvanised Steel: 11.5 x10 (1/°C) |

SERVICE CONDITIONS

| Ambient Temperature | -5°C - 50°C |

| Wind Pressure | 80 – 130kg/m |

| Seismic Acceleration | 0.12 - 0.05g |

| Isokeraunic level | 10 – 18 |

| relative Humidity | 5 – 100% |

TECHNICAL DATA

| Numbers of Wires | Modules of Elasticity | Coeficient of linear Expansion | |||

| AL | STEEL | Kg/mm2 | Lb/in2 | 1/Cº | 1/Fº |

| 6 | 1 | 81 | 11.5 x106 | 19.1 x10-6 | 10.6 x10-6 |

| 6 | 7 | 77 | 11.0 x106 | 19.8 x10-6 | 11.0 x10-6 |

| 12 | 7 | 107 | 15.2 x106 | 15.3 x10-6 | 8.5 x10-6 |

| 18 | 1 | 67 | 9.5 x106 | 21.2 x10-6 | 11.8 x10-6 |

| 24 | 7 | 74 | 10.5 x106 | 19.6 x10-6 | 10.9 x10-6 |

| 26 | 7 | 77 | 10.9 x106 | 18.9 x10-6 | 10.5 x10-6 |

| 28 | 7 | 79 | 11.2 x106 | 18.4 x10-6 | 10.2 x10-6 |

| 30 | 7 | 82 | 11.6 x106 | 17.8 x10-6 | 9.9 x10-6 |

| 30 | 19 | 80 | 11.4 x106 | 18.0 x10-6 | 10.0 x10-6 |

| 32 | 19 | 82 | 11.7 x106 | 17.5 x10-6 | 9.7 x10-6 |

| 54 | 7 | 70 | 9.9 x106 | 19.3 x10-6 | 10.7 x10-6 |

| 54 | 19 | 68 | 9.7 x106 | 19.4 x10-6 | 10.8 x10-6 |

Parameters

| AMERICAN STANDARD ASTM B232-B232 M1999 | ||||||||

| Code Word | Stranding | Stranding | Nominal Overall Diameter | Mass | Rated Strength | |||

| Aluminium Wires | Steel Wires | |||||||

| Number | Diameter | Number | Diameter | |||||

| mm | mm | mm | kg/Km | kN | ||||

| Raven | 6/1 | 6 | 3.37 | 1 | 3.37 | 10.11 | 216.08 | 19.48 |

| Minorca | 12/7 | 12 | 2.44 | 7 | 2.44 | 12.22 | 411.18 | 50.26 |

| Quail | 6/1 | 6 | 3.78 | 1 | 3.78 | 11.35 | 272.04 | 23.58 |

| Leghorn | 12/7 | 12 | 2.69 | 7 | 2.69 | 13.46 | 499.28 | 60.5 |

| Guinea | 12/7 | 12 | 2.92 | 1 | 2.92 | 14.63 | 589.76 | 71.17 |

| Pigeon | 6/1 | 6 | 4.25 | 1 | 4.25 | 12.75 | 343.02 | 29.45 |

| Dotterel | 12/7 | 12 | 3.08 | 7 | 3.08 | 15.42 | 656.13 | 76.95 |

| Dorking | 12/7 | 12 | 3.2 | 7 | 3.2 | 16.03 | 707.92 | 83.18 |

| Brahma | 16/19 | 16 | 2.86 | 19 | 2.48 | 18.14 | 1003.91 | 126.33 |

| Cochin | 12/7 | 12 | 3.37 | 7 | 3.37 | 16.87 | 783.96 | 92.08 |

| Penguin | 6/1 | 6 | 4.77 | 1 | 4.77 | 14.3 | 432.76 | 37.14 |

| Partidge | 26/7 | 26 | 2.57 | 7 | 2 | 16.31 | 546.01 | 50.26 |

| Waxwing | 18/1 | 18 | 3.09 | 1 | 3.09 | 15.47 | 430.23 | 30.69 |

| Ostrich | 26/7 | 26 | 2.73 | 7 | 2.12 | 17.27 | 613.42 | 56.49 |

| Oriole | 30/7 | 30 | 2.69 | 1 | 2.69 | 18.82 | 783.37 | 76.95 |

| Linnet | 26/7 | 26 | 2.89 | 7 | 2.25 | 18.29 | 687.53 | 62.72 |

| Widgeon | 18/1 | 18 | 3.47 | 1 | 3.47 | 17.37 | 542.88 | 38.7 |

| Lark | 30/7 | 30 | 2.92 | 7 | 2.92 | 20.47 | 925.34 | 90.3 |

| Ibis | 26/7 | 26 | 3.14 | 7 | 2.44 | 19.89 | 812.54 | 72.51 |

Product show

Work Shop